cuisinart toaster oven instruction manual

This manual provides operating instructions for a Cuisinart Toaster Oven Broiler. It describes the functions of the various buttons on the control panel, including buttons to set the time, temperature, and cooking mode. It also includes instructions for cleaning the oven.

Important Safeguards

When using an electrical appliance, basic safety precautions should always be followed, including the following⁚

- Read all instructions.

- Unplug from outlet when not in use and before cleaning.

- To protect against electrical shock, do not immerse cord, plugs, or appliance in water or other liquids.

- Close supervision is necessary when any appliance is used by or near children.

- Do not operate any appliance with a damaged cord or plug or after the appliance malfunctions or has been dropped or damaged in any manner. Return the appliance to the nearest authorized service facility for examination, repair, or electrical or mechanical adjustment.

- The use of accessory attachments not recommended by the appliance manufacturer may result in fire, electric shock, or injury.

- Do not use outdoors.

- Do not let cord hang over edge of table or counter or touch hot surfaces.

- Do not place on or near a hot gas or electric burner, or in a heated oven.

- Extreme caution must be used when moving an appliance containing hot oil or other hot liquids.

- Always unplug the appliance from the electrical outlet before cleaning.

- To disconnect, grasp the plug and pull from the outlet. Never pull on the cord.

- Do not use appliance for other than intended use.

- Do not place on or near any hot surfaces.

- Do not use harsh abrasive cleaners or scouring pads on the inside or outside of the appliance.

- Do not use the oven to heat food in a sealed container.

- Do not place the appliance on an unstable surface.

- Do not use the appliance with a wet cord or plug.

- Do not place the appliance on a damp surface.

- Do not operate the appliance with a damaged cord or plug.

- Do not operate the appliance with a loose or broken part.

- Do not attempt to repair the appliance yourself.

- Do not use the appliance for other than intended use.

Special Cordset Instructions

This appliance has a polarized plug (one blade is wider than the other). To reduce the risk of electric shock, this plug is intended to fit into a polarized outlet only one way. If the plug does not fit fully into the outlet, reverse the plug. If it still does not fit, contact a qualified electrician. Do not attempt to modify the plug in any way.

A short power-supply cord is provided to reduce the risk resulting from becoming entangled in or tripping over a longer cord. Longer extension cords are available and may be used if care is exercised in their use. If an extension cord is used⁚

- The marked electrical rating of the extension cord should be at least as great as the electrical rating of the appliance.

- The extension cord should be a grounding-type 3-wire cord.

- The cord should be arranged so that it will not drape over the countertop or tabletop where it can be pulled on by children or tripped over.

If the appliance is used on a circuit with other appliances, the circuit may become overloaded. It is recommended that the appliance be operated on its own circuit.

Features and Benefits

The Cuisinart Toaster Oven Broiler is a versatile appliance that can be used for a variety of cooking tasks. Its features include⁚

- Convection cooking⁚ This feature uses a fan to circulate hot air around the food, resulting in faster and more even cooking.

- Broiling⁚ The broiler element allows you to brown and crisp foods quickly.

- Baking⁚ The oven can be used to bake a variety of dishes, from cookies to casseroles.

- Toasting⁚ The toaster oven can toast bread, bagels, and other items to perfection.

- Reheating⁚ The oven can be used to reheat leftovers.

- Timer⁚ The oven has a timer that allows you to set the cooking time and be alerted when the food is done.

- Temperature control⁚ The oven has a temperature control dial that allows you to set the desired cooking temperature.

The Cuisinart Toaster Oven Broiler is a great way to add versatility to your kitchen. It is perfect for small kitchens or for those who want to avoid heating up their full-size oven.

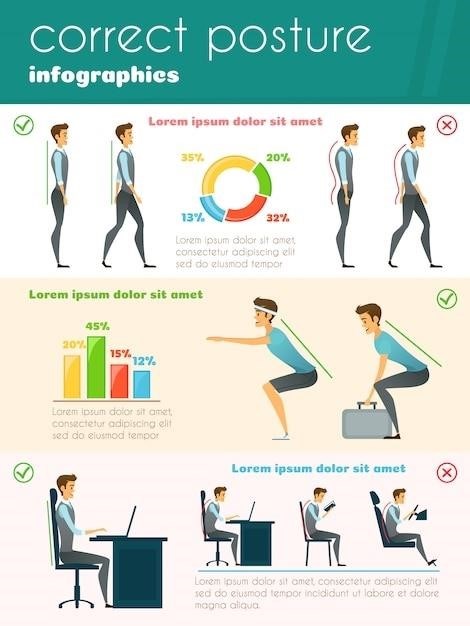

Oven Rack Position Guide

The oven rack position guide helps you determine the best rack position for different types of food. The rack positions are typically labeled A, B, and C, with A being the highest position and C being the lowest. Here are some general guidelines for using the rack positions⁚

- Rack Position A⁚ This position is best for baking pizzas, cakes, chicken, or muffins. The higher position allows for more even heat distribution and prevents the bottom of the food from burning.

- Rack Position B⁚ This position is suitable for baking nachos, quesadillas, or potatoes. It provides a good balance of heat from above and below, ensuring the food cooks evenly.

- Rack Position C⁚ This position is generally used for broiling. It allows the food to be closer to the broiler element, resulting in faster and more intense browning.

It’s important to note that these are just general guidelines. The specific rack position you use may vary depending on the size and type of food you are cooking. Refer to the specific recipe instructions for recommendations on the optimal rack position.

General Guidelines

Before using your Cuisinart Toaster Oven, it’s essential to familiarize yourself with these general guidelines to ensure safe and efficient operation⁚

- Preheat the oven⁚ Preheat the oven according to the recipe instructions. Preheating allows for more even cooking and helps prevent food from sticking to the pan. For delicate items like cakes and muffins, preheating is especially important.

- Use the correct rack position⁚ Refer to the oven rack position guide to determine the best position for your food. This ensures even heat distribution and prevents burning.

- Avoid overcrowding the oven⁚ Allow adequate space between food items and the sides of the oven. Overcrowding can hinder airflow and lead to uneven cooking.

- Monitor cooking time⁚ Keep an eye on your food while it’s cooking, and adjust the cooking time as needed. Use a timer to help you track the time accurately.

- Use oven mitts⁚ Always use oven mitts when handling hot trays, pans, or food. The oven and its components can get very hot during operation.

By following these general guidelines, you can ensure that your Cuisinart Toaster Oven operates safely and efficiently, producing delicious results.

Operation

Your Cuisinart Toaster Oven offers a variety of functions to suit your culinary needs. Here’s a breakdown of how to operate the oven for different tasks⁚

- Toast⁚ Select the “Toast” function and adjust the browning level using the dial. Insert bread slices into the slots and watch as the oven crisps them to perfection.

- Bagel⁚ The “Bagel” function is designed for toasting bagels. Select this function and insert your bagel with the cut side facing inward. The oven will toast the bagel evenly.

- Bake⁚ For baking, set the desired temperature and select the “Bake” function. Place your food on the appropriate rack position and bake for the recommended time.

- Reheat⁚ The “Reheat” function is perfect for warming up leftovers. Select this function and set the temperature to the desired level. Place your food in the oven and reheat until warm.

- Convection Button⁚ The “Convection” button activates the fan, which circulates hot air throughout the oven. This function is ideal for faster and more even cooking. When using the “Convection” button, consider adjusting the cooking time and temperature accordingly.

Always refer to your specific model’s instruction manual for detailed instructions and recommended settings for each function.

Toast

To achieve perfectly toasted bread, follow these simple steps⁚

- Set the Function Dial⁚ Rotate the dial to the “Toast” position.

- Choose Browning Level⁚ Using the “Toast Shade” dial, select the desired browning level. The numbers 1 through 6 correspond to light to dark browning.

- Insert Bread⁚ Carefully place your bread slices into the designated slots within the oven. Ensure they are centered and not touching.

- Start Toasting⁚ The oven will automatically begin toasting once you have inserted the bread. Watch as the bread browns to your preferred shade.

- Remove Toast⁚ Once the toasting cycle is complete, the oven will signal the end. Use the bread lift to safely remove your toasted slices.

For optimal results, always refer to your specific model’s instruction manual for recommended toasting times and settings for various bread types.

Bagel

The Cuisinart Toaster Oven is designed to achieve perfectly toasted bagels with a crisp exterior and a soft, warm interior. Here’s how to use the bagel function⁚

- Select the Bagel Function⁚ Turn the Function Dial to the “Bagel” position. This activates the special settings designed for bagels.

- Choose Browning Level⁚ Use the “Toast Shade” dial to select the desired browning level. The numbers 1 through 6 represent light to dark browning, allowing you to customize your preference.

- Position the Bagel⁚ Carefully place your bagel in the designated slot within the oven. Ensure it’s centered and not touching any other parts of the oven.

- Begin Toasting⁚ The oven will automatically start toasting once the bagel is inserted. Observe the browning process to ensure it reaches your desired shade.

- Remove the Bagel⁚ Once the toasting cycle is complete, the oven will signal the end. Use the bread lift to safely remove your toasted bagel.

Remember to always refer to your specific model’s instruction manual for recommended toasting times and settings for different bagel sizes and varieties.

Bake

The Cuisinart Toaster Oven offers versatile baking capabilities, allowing you to prepare a variety of dishes from cookies to casseroles. Follow these steps for successful baking in your Cuisinart Toaster Oven⁚

- Preheat the Oven⁚ Before baking, preheating the oven is crucial for ensuring even cooking. Set the Temperature Dial to your desired baking temperature and the ON/Toast Shade Dial to the “ON” position. Allow the oven to preheat for at least 5 minutes, especially for delicate items like cakes and muffins.

- Choose the Bake Function⁚ Turn the Function Dial to the “Bake” position to activate the appropriate heating elements for baking.

- Select Baking Temperature⁚ Set the Temperature Dial to the recommended temperature for your recipe. Check your recipe for specific temperature guidelines.

- Position the Baking Rack⁚ Select the appropriate rack position for your recipe based on the Oven Rack Position Guide in your manual. Generally, use the higher rack for items that need more browning and the lower rack for items that require more even cooking.

- Place Food in the Oven⁚ Carefully place your prepared food on the baking rack. Avoid overcrowding the oven, as this can impede airflow and affect cooking.

- Monitor Baking Time⁚ Check your food periodically during the baking process, using a toothpick or cake tester to ensure doneness. Adjust baking times as needed.

- Turn off the Oven⁚ Once your food is cooked through, turn off the oven by setting the ON/Toast Shade Dial to the “OFF” position.

For optimal baking results, always refer to your specific model’s instruction manual for recommended baking times and temperatures for various dishes.

Reheat

Reheating leftovers in your Cuisinart Toaster Oven is a quick and efficient way to enjoy a warm meal without the need for a full oven. Here’s a step-by-step guide to reheating food in your Cuisinart Toaster Oven⁚

- Select the Reheat Function⁚ Turn the Function Dial to the “Reheat” position. This setting optimizes the oven’s heating elements for reheating, ensuring even and gentle warmth.

- Choose the Temperature⁚ Set the Temperature Dial to a moderate temperature, usually between 300°F and 350°F (150°C and 175°C). Avoid using high temperatures, which can lead to overcooking or burning.

- Position the Food⁚ Place your leftovers on a suitable oven-safe dish or directly on the oven rack, depending on the type of food. Ensure the food is spread out evenly for efficient reheating.

- Set the Timer⁚ Set the ON/Oven Timer Dial to the recommended reheating time. Start with a shorter time and adjust as needed. Reheating times will vary based on the type of food and its initial temperature.

- Monitor the Food⁚ Check the food periodically during reheating to ensure it’s warm throughout. Use a fork or knife to check the internal temperature. Avoid overcooking, which can dry out the food.

- Turn off the Oven⁚ Once your food is heated through, turn off the oven by setting the ON/Toast Shade Dial to the “OFF” position. Remove the food carefully and enjoy your warm leftovers.

For optimal reheating results, consider covering your food with foil or a lid to trap heat and maintain moisture. Adjust reheating times and temperatures as needed for different food types and quantities.